Category is loading...

Building the Future

Before It’s Built

Industrial AI isn’t coming – it’s already here.

Wandelbots NOVA links your production systems to Europe’s new AI backbone.

What Can You Do Today

-

Connect your existing systems, make production data accessible and standardised.

-

Create digital twins of critical assets using NOVA and Omniverse.

-

Train AI models virtually before implementation.

-

Deploy and iterate in your live environment.

Each step builds readiness for the Sovereign Industrial AI Cloud and protects the investments you already made.

Talk to our team about enabling your environment with NOVA and preparing your factory for the Sovereign Industrial AI Cloud.

What It Means

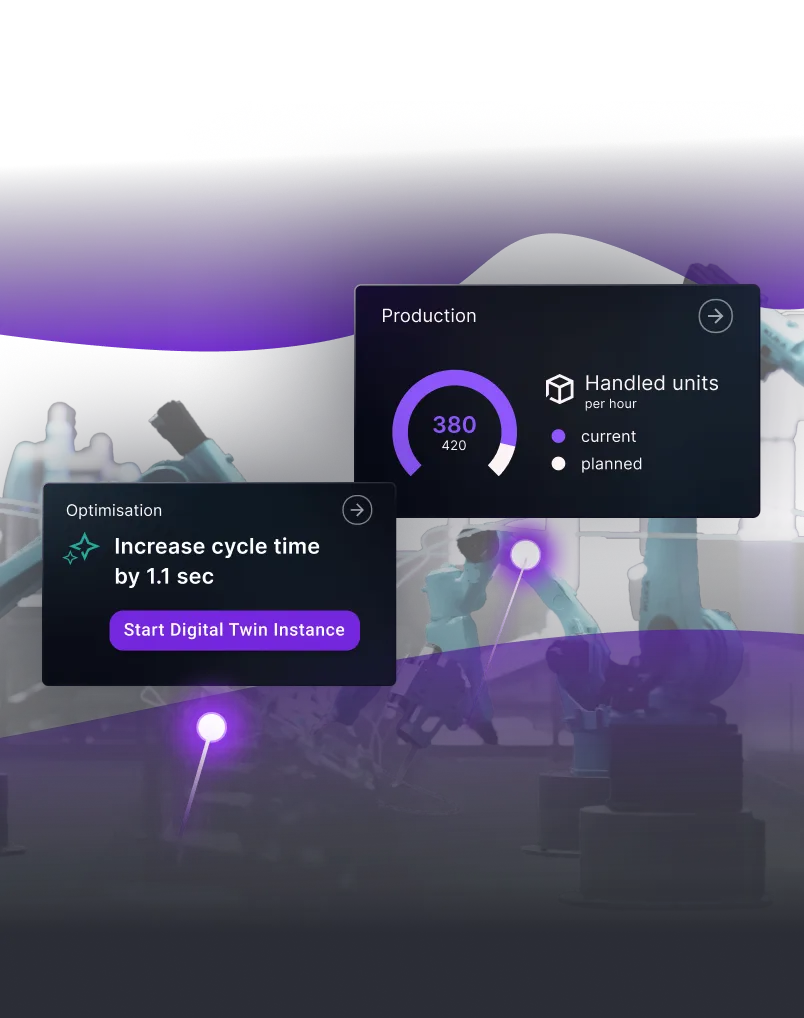

Wandelbots NOVA and NVIDIA Omniverse make automation software-defined.

Model, train and optimise production lines virtually – then deploy those learnings directly into real operations.

Learn more about Wandelbots & Nvidia.

How It Works

With Wandelbots NOVA, industrial robotics becomes software-defined. Engineers can design, simulate, and deploy automation workflows with modern tools, using the same software layer for both digital twins and physical robots on the shopfloor.

Why It Matters

Competitiveness in manufacturing is shifting from cost to intelligence. Speed, quality and flexibility now depend on how fast your systems can learn.

By connecting existing assets through NOVA and the Sovereign Industrial AI Cloud, you turn data into performance – shortening planning cycles, protecting investments and keeping production economically viable in Europe.

See It In Action

Real examples from Volkswagen and

EDAG show how NOVA and NVIDIA Omniverse close the loop between digital planning and physical automation.

This is where Sovereign Industrial AI becomes tangible: data, machines and people working in one continuous feedback loop – from model to motion.